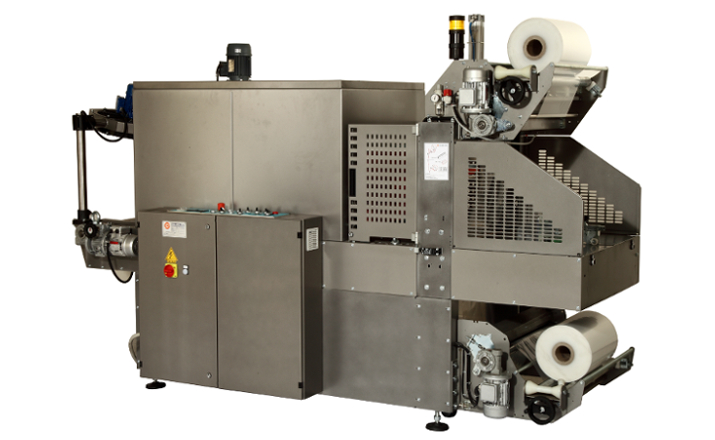

Semi-automatic machines with adjustable pusher to load the product manually on the infeed surface. These machines are suitable for packing any product. Production capacity of 5-12 packs/min.

Main features

- Max. width of the pack depends on its height

- Pneumatic pusher in line with scraper

- 700 mm (MS 70)-900 mm (MS 90) "hot bar" – sealing bar type with film cut by cold blade

- Safety photocell that blocks the sealing bar if it finds an obstacle in its path

- Passage opening under the sealing bar 380 mm

- Automatic upper and lower system to unwind the film reel with dragging rollers

- Heat-shrinking tunnel Length 1300 mm for mod. (MS 70) - 1500 mm for mod. (MS 90) with air circulation system

- Adjustable speed of the conveyor belt in the tunnel

- Installed power 20 kW for mod. (MS 70) – 27 kW for mod. (MS 90). Average electricity consumption is reduced by about 40% during normal operation

- Air consumption 150 nl/min

- Pneumatic components that work with non-lubricated dry air

- Switch for manual or semi-automatic operation

- Voltage: 400 V 3-phase + N + E / 50 Hz

- Machines compatible with Machinery Directive 2006/42/EC

Options

- Guides for product containment after the sealing bar

- Pack cooling unit positioned at the Tunnel outfeed

- Self-sizing mechanical presser on the pack

- Film presser rollers

- Side rails inside the Tunnel for product protection

- Machine mounted on wheels

- Section of the conveyor with thick rollers and positioned below the pack cooling unit at the Tunnel outfeed. This solution is ideal for groups of products that are only packed with film

- Upper and lower film reel insertion rollers to make replacement easier for the operator

- Signal system that indicates the end of the reel

- Automatic upper and lower film reel centring system by means of a handwheel